Oro Orodjarna d.o.o. is a manufacturer of injection molding tools, where precision is not an added value but a basic requirement. High-precision CNC machining, complex tool assemblies, and orders for the automotive industry mean that production must operate in constant alignment—without guesswork, without downtime, and without surprises.

As production volumes grew and processes became more complex, it became increasingly difficult to maintain control over what was actually happening on the shop floor—in real time, not retrospectively. Manual data entry, delays in detecting issues, and planning based on estimates were becoming a major bottleneck.

Key wins achieved:

-

Up to 50% faster detection of machine downtime

-

Up to 20% higher production planning accuracy

-

Elimination of manual work order logging

-

Less scrap material and fewer unnecessary inventories

If you are considering optimizing day-to-day processes, AI consulting at Kalmia is often a good first step to assess opportunities and risks.

Challenge

Limited production visibility and inefficient planning

With its existing way of working, ORO faced challenges typical of modern manufacturing—challenges that can quickly become costly:

-

Working hours and machine status were recorded manually

-

Machine operation and process temperatures were not visible in real time

-

Production planning was not based on actual real-time data

-

Downtime was detected with a delay, after it had already caused time losses and inefficiencies

Production planning relied mainly on experience and historical data rather than the actual real-time situation. This made work scheduling more difficult, increased the risk of deviations, and introduced additional unpredictability into the production process.

Solution

A comprehensive system powered by IoT, MES, and artificial intelligence

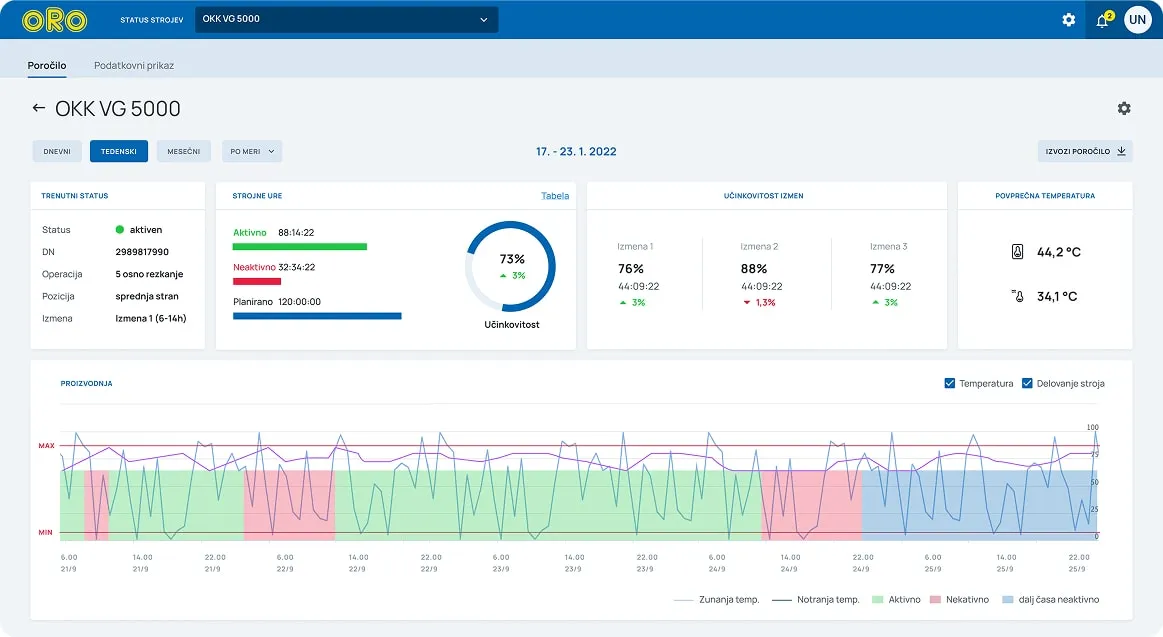

For ORO, we designed and implemented a comprehensive digital manufacturing system that connects machines, production processes, and the existing ERP into a unified data environment.

The solution includes:

-

IoT sensors for real-time monitoring of machine status and process temperatures

-

An MES system (with bi-directional ERP integration) for full visibility of work orders

-

AI models for forecasting and optimizing the production plan

-

A modular architecture that allows gradual upgrades based on production needs

The purpose of the system is not to change existing processes, but to establish a reliable data foundation. This enables better planning, improved control, and - most importantly - more informed decision-making in daily production operations.

How It Works in Practice

In practice, the system becomes part of everyday work without adding extra burden for employees:

-

Machine operators have real-time insight into basic operating status and key process data

-

Production managers monitor machine utilization and work order progress via a central dashboard

-

Production planning relies on historical data and current machine utilization, rather than estimates

-

Deviations between planned and actual processing times are visible immediately, enabling real-time plan adjustments—when they have the greatest impact

The system requires no additional manual data entry; information is collected and updated automatically, without duplicated work.