Weiler Abrasives is a global manufacturer of abrasive solutions for industrial grinding, cutting, and surface conditioning applications. With a legacy of innovation and customer-centricity, Weiler is dedicated to helping professionals optimize performance and safety in their operations. The company is recognized for its commitment to quality, durability, and continuous improvement across a wide range of abrasive products.

Website: https://emea.weilerabrasives.com

The Challenge

Building Trust, Intelligence, and Efficiency in Abrasive Usage

Weiler Abrasives set out to modernize its customer experience with intelligent tools to verify product authenticity, ensure safe usage, and optimize abrasive replacement cycles. Their goal: to combine cutting-edge digital technologies with real-time data for smarter, safer, and more efficient operations.

To achieve this, three innovative applications were envisioned:

- Abrasive Authenticity App – A blockchain-based mobile solution to verify abrasive genuineness through QR codes.

- Smart Abrasive App – A sensor-integrated system to monitor usage patterns and ensure optimal and safe abrasive performance.

- Smart Planning Application – A predictive maintenance system powered by AI and machine learning to forecast the optimal teardown and replacement schedule for abrasives.

Our Approach & Technology Stack

We engineered a modular, cloud-native platform integrating sensors, AI models, blockchain, and mobile/web interfaces. This flexible and scalable infrastructure supports real-time decision-making and long-term planning with minimal friction.

Core Components:

- Mobile & Web Applications – Interfaces for QR scanning, real-time usage feedback, and planning tools.

- Backend Services – APIs, sensor integration, data processing, and ERP/data warehouse connectivity.

- AI & ML Engine – Predictive models trained on historical usage data to anticipate abrasive wear and optimize replacement.

- Blockchain Layer – Immutable authenticity verification based on product-specific manufacturing data.

- IoT Hardware – Sensors and hubs for capturing vibration, speed, and acoustic signatures.

Key Features Delivered

01 Abrasive Authenticity Verification

- QR Code Scanning for instant identification.

- Blockchain Validation ensures data integrity via cryptographic hashing.

- ERP/Data Warehouse Integration links production and identity data.

- Cost-Efficient Blockchain Use through batch processing of daily abrasive entries.

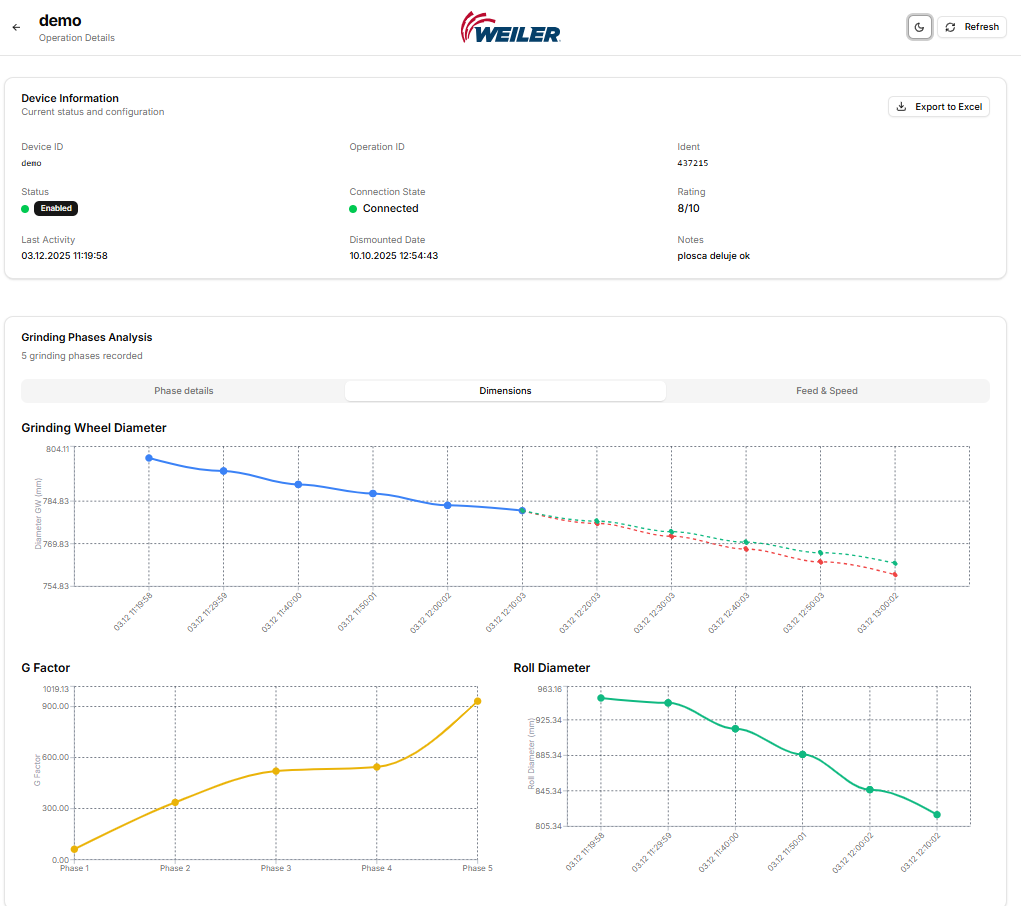

02 Smart Abrasive Usage Monitoring

- Sensors on Abrasives collect performance metrics during use.

- Real-Time Data Transmission via always-connected sensor hubs.

- Mobile Feedback Loop provides safety and performance alerts to operators.

- Web Dashboard visualizes historical and live data for operations teams.

03 Smart Planning with AI & Machine Learning

- Predictive Modeling: Machine learning models analyze historical sensor data—including vibration patterns, speed, and abrasive type—to forecast teardown timelines.

- Optimized Replacement Cycles: The AI recommends the ideal time to replace abrasives, balancing safety, performance, and cost-efficiency.

- Data-Driven Maintenance: Reduces unplanned downtime and maximizes the lifespan of abrasive tools.

- Dynamic Adjustment: As new data flows into the system, models continue to learn and refine their predictions.

- Cost and Efficiency Gains: Enables maintenance teams to act proactively, minimizing waste and maximizing operational uptime.

Modular & Scalable Architecture

- Scalable Infrastructure supports growth from 10,000 to over 1 million abrasives.

- Modular Design allows integration of additional features like European material passport compliance or more sensor types.

- Multi-Tiered Storage separates real-time and analytical data for performance optimization.